Introduction:

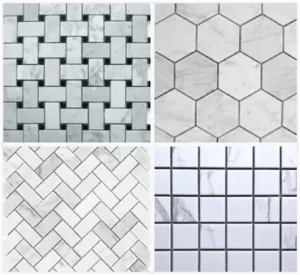

In this article, we’ll explore the benefits of using a Mosaic Cutting Machine for tile baseboard production. This advanced equipment is highly recommended for manufacturing plants, offering various advantages to tile baseboard manufacturers.

- Efficient Precision, Increased Productivity

The Mosaic Cutting Machine delivers precise and efficient cutting of tile baseboards. Compared to manual methods, its speed and accuracy significantly enhance production efficiency, ensuring timely order completion.

- Versatility and Customization

With flexible cutting capabilities, the Mosaic Cutting Machine can create tile baseboards in various sizes and shapes, catering to personalized demands. Straight lines or curves, it effortlessly meets customization needs.

- Minimal Waste, Cost-Effective

The machine’s intelligent optimization and precision reduce material waste, leading to cost savings for manufacturing plants and ensuring a sustainable approach to production.

- Improved Safety, Reduced Labor

Automated operation reduces worker contact with the cutting process, enhancing workplace safety. Additionally, less physical labor is required, boosting efficiency and lowering labor costs.

Conclusion:

The Mosaic Cutting Machine brings numerous advantages to tile baseboard manufacturers. Its efficient precision cutting, versatility, waste reduction, and improved safety make it the ideal choice for manufacturing plants. By leveraging the Mosaic Cutting Machine’s capabilities, tile baseboard manufacturers can meet customer demands effectively, enhance productivity, and thrive in a competitive market. Invest in the Mosaic Cutting Machine now to lead the future of tile baseboard production!

Please contact us if you need more details about the machine

Tel: 86 18948983020

Email: [email protected]