Technical parameter:

| Woek platform size | Way of working | Size setting method | Machine size |

|---|---|---|---|

| 3600*1700mm | Dicing | CAD drawing | 6000*2000*1500mm |

| Effective cutting size | Cutting head automatic device | Cutting speed | Package size |

| 3600*1700mm | Air pressure lift | 5-10m/min | 3800*2100*2500mm |

| Sawing spindle motor power | Blade diameter | Weight | |

| 15KW/set | 0.6mm | 2000KG |

Video

Product details

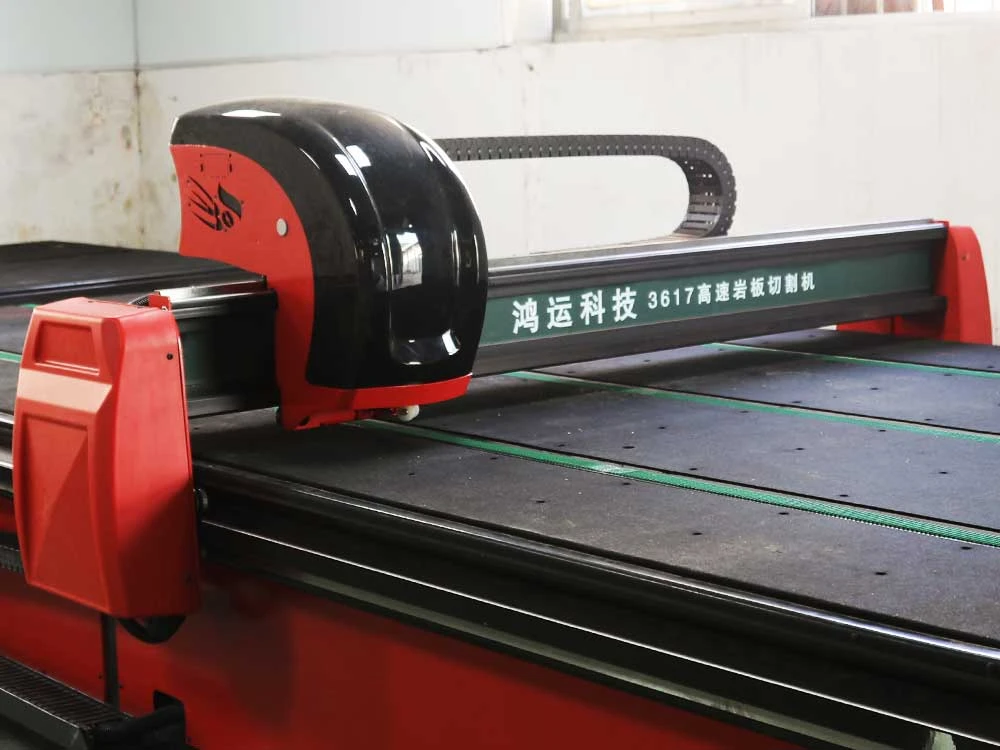

The cutting thickness is: 3-15mm, can cut up to 8 meters per minute, And specially developed 6mm thick 6061 high-strength stress-relieving industrial aluminum beams,ensure the lifespan and load-bearing capacity of the aluminum beam;The large-scale milling machine processes the mounting surface to ensure the verticality and straightness of the mounting surface and improve the accuracy. long service life and stable performance, and the optimization rate can reach 99%.

Using high-strength national standard carbon steel, robot full welding process, overall heat treatment of the fuselage, stress relief aging treatment, to ensure that the fuselage is not deformed and flat;

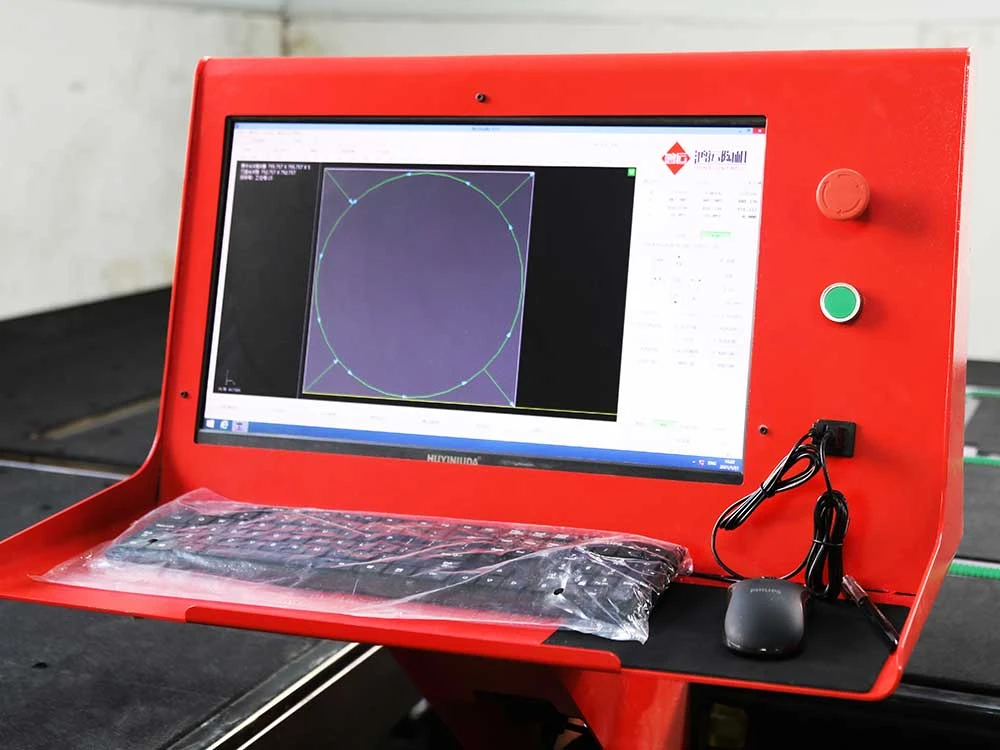

It adopts dual-drive high-horsepower servo motors, high speed and high precision, and adopts special cutting head for Italian slate; The machine is equipped with a laser positioning system, which can be arranged irregularly, and can be cut arbitrarily;

An imported scribe can cut 7000-10000 meters of slate countertops, low cost;

Using Shanghai Weihong cutting system can optimize the best cutting path and greatly improve the production efficiency under the premise of ensuring material saving.

Our advantages

Foshan Hoyun Ceramic Machinery Co., Ltd.

Which is located at No. 1, Baishaqiao Village, Third Industrial Zone, Shishan Town, Nanhai District, Foshan City, Guangdong Province, China. It is a professional manufacturer specializing in the production of CNC tile cutting machines, water jet cutting machines, manual tile cutting machines, ceramic tiles chamfering machine, edge grinding machine, fillet polishing machine, mosaic slotting machine and other ceramic/sintered stone deep processing equipment.