A wet stone cutting saw is crucial for efficient stone processing in factories. Follow these steps to set it up correctly:

- Choose the Saw: Select a saw suitable for your stone type and cutting needs. Consider power, precision, and user-friendliness.

- Prepare the Site: Pick a stable, level location for the saw, away from hazards. Clear the area of any obstructions.

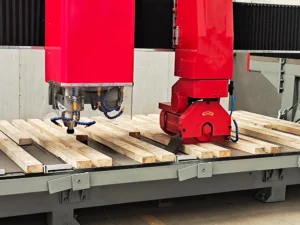

- Mount the Saw: Secure the saw to the floor or stand using the manufacturer’s instructions. Ensure it’s stable and level.

- Install the Blade: Attach the blade correctly, according to the saw’s specs. Choose the right blade type for your stone.

- Adjust the Cutting Depth: Set the depth based on stone thickness to ensure clean cuts without damage.

- Connect Coolant: Attach the coolant pump and hoses, and fill the reservoir. Aim the nozzle at the cutting area.

- Test the Saw: Test the saw on a small stone sample to check for correct setup and performance.

- Implement Safety: Follow safety protocols, wear PPE, and maintain a clean workspace. Train employees on safe saw operation.

By following these steps, you’ll have a properly configured wet stone cutting saw for efficient and safe stone cutting in your factory.