Dear readers,

Welcome to our blog. Today, we’re going to delve into the multifaceted charm of “Bridge Saws” in the realm of stone cutting. Without a doubt, bridge saws are reshaping the landscape of the stone processing industry with unprecedented efficiency and creativity.

Bridge Saws: Leading the Revolution in Stone Cutting

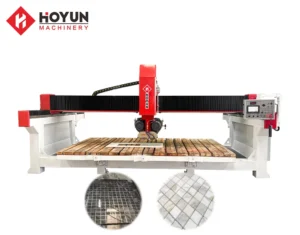

A bridge saw is a stone cutting device that amalgamates precision, automation, and creativity. Its functionality revolves around a large beam spanning the cutting area, carrying cutting tools. Here’s why bridge saws are so captivating:

Striking the Perfect Balance Between Cutting Precision and Speed

Whether it’s marble, granite, or any other type of stone, bridge saws are renowned for their high precision cutting. They can cut virtually any shape and size, bringing to life the visions of designers and artisans. Moreover, bridge saws can achieve high efficiency production while maintaining superior quality, significantly shortening production cycles.

The Introduction of Automation Technology

With the advancement of automation technology, bridge saws have become smarter. Through advanced control systems and sensors, they can monitor the cutting process in real time and make necessary adjustments to ensure each piece of stone meets precise specifications. This not only reduces the risk of human errors but also greatly enhances production efficiency.

Infinite Creativity: The Potential of Customized Cutting

Bridge saws are not merely machines; they are tools of creation. They can cut unique shapes and patterns according to the designer’s imagination, injecting distinctive character into stone products. This opens up boundless creative possibilities for interior design, architecture, and art.

A Dual Consideration of Environmental Impact and Benefits

Increasing environmental awareness has led to the development of more eco-friendly cutting techniques. Some bridge saws use waterjet cutting technology, utilizing high-speed water jets for cutting, which reduces dust and waste production. This not only contributes to environmental protection but also lowers production costs.

Looking Ahead: The Evolution of Bridge Saws

As technology advances, bridge saws will continue to evolve, becoming more intelligent and efficient. We can anticipate more innovations, higher cutting precision, and broader applications.

Conclusion

The multifaceted allure of bridge saws in the stone processing domain is undeniably shaping the future of the industry. Their attributes of high precision, automation, creativity, and environmental-friendliness mark significant advancements in cutting processes. Not only do they boost production efficiency, but they also facilitate the creation of more personalized stone products.

Thank you for reading our blog. If you have more questions about bridge saws or would like to learn more, please don’t hesitate to contact us.